Efficiency is everything, especially in the current dynamic business environment. Streamlined operations reduce costs, improve customer satisfaction, and drive business growth. One of the key methods for achieving operational efficiency is Process Analysis—a critical component of Business Process Management (BPM). By identifying bottlenecks, conducting root cause analysis, and using performance metrics and KPIs, businesses can refine their processes for optimal performance.

In this article, we’ll explore what Process Analysis is, its key components, and how it helps businesses identify inefficiencies and implement meaningful improvements.

What is Process Analysis?

Process Analysis is the systematic approach to studying and evaluating business processes to identify inefficiencies, bottlenecks, and areas for improvement. It involves dissecting workflows, tasks, and procedures to understand how they function and what impact they have on the overall performance of the organization.

The goal of Process Analysis is to provide actionable insights that can help businesses optimize their operations. This can lead to faster execution, improved quality, lower costs, and better customer satisfaction. The analysis often involves tools such as flowcharts, process maps, and data-driven evaluations that offer a clear view of where breakdowns occur and how processes can be streamlined.

1. Identifying Bottlenecks and Inefficiencies

One of the primary objectives of Process Analysis is to uncover bottlenecks—the points in a process where delays or slowdowns occur. Bottlenecks can significantly hinder efficiency and productivity, leading to wasted time, resources, and increased costs.

Common types of bottlenecks include:

- Task Bottlenecks: Certain tasks may take longer than others, causing delays in subsequent steps.

- Resource Bottlenecks: Limited availability of essential resources, such as equipment or personnel, can create backups.

- Decision-Making Bottlenecks: Lengthy approvals or decision-making processes that slow down the workflow.

By conducting a thorough analysis, businesses can identify these bottlenecks and develop strategies to address them—whether through automation, restructuring workflows, or reallocating resources.

2. Root Cause Analysis: Digging Deeper into Problems

When inefficiencies or errors occur within a process, it’s crucial to understand the root cause of the problem, not just the symptoms. This is where root cause analysis becomes important.

Two popular tools for root cause analysis include the Fishbone Diagram (also known as the Ishikawa or Cause-and-Effect Diagram) and the 5 Whys technique.

- Fishbone Diagram: This tool helps businesses visually map out the potential causes of a problem, organizing them into categories such as people, methods, equipment, and materials. The visual representation makes it easier to analyze the different factors contributing to a specific issue.

- 5 Whys: This simple yet powerful technique involves asking “why” five times (or more) to drill down into the root cause of an issue. Each answer leads to the next “why,” helping you uncover the fundamental reason behind a problem. This method helps ensure that businesses are addressing the core issue, not just treating surface-level symptoms.

Using these tools as part of Process Analysis enables businesses to gain a clear understanding of underlying problems and take corrective action that leads to long-term improvements.

3. Performance Metrics and Key Performance Indicators (KPIs)

To measure the success and efficiency of business processes, organizations rely on performance metrics and Key Performance Indicators (KPIs). These tools help monitor the effectiveness of processes and track progress toward goals.

- Performance Metrics: These are quantifiable measures used to assess how well a process is functioning. Metrics can include things like cycle time, error rates, throughput, and resource utilization. By tracking these metrics, businesses can identify trends, measure efficiency, and determine whether changes are needed.

- Key Performance Indicators (KPIs): KPIs are specific, strategic metrics that align with a company’s overall goals. They serve as critical indicators of whether a process is meeting its objectives. For example, KPIs for customer service might include response times, first-contact resolution rates, and customer satisfaction scores.

By establishing and regularly reviewing KPIs, businesses can ensure they are on the right track and that process improvements are delivering measurable benefits.

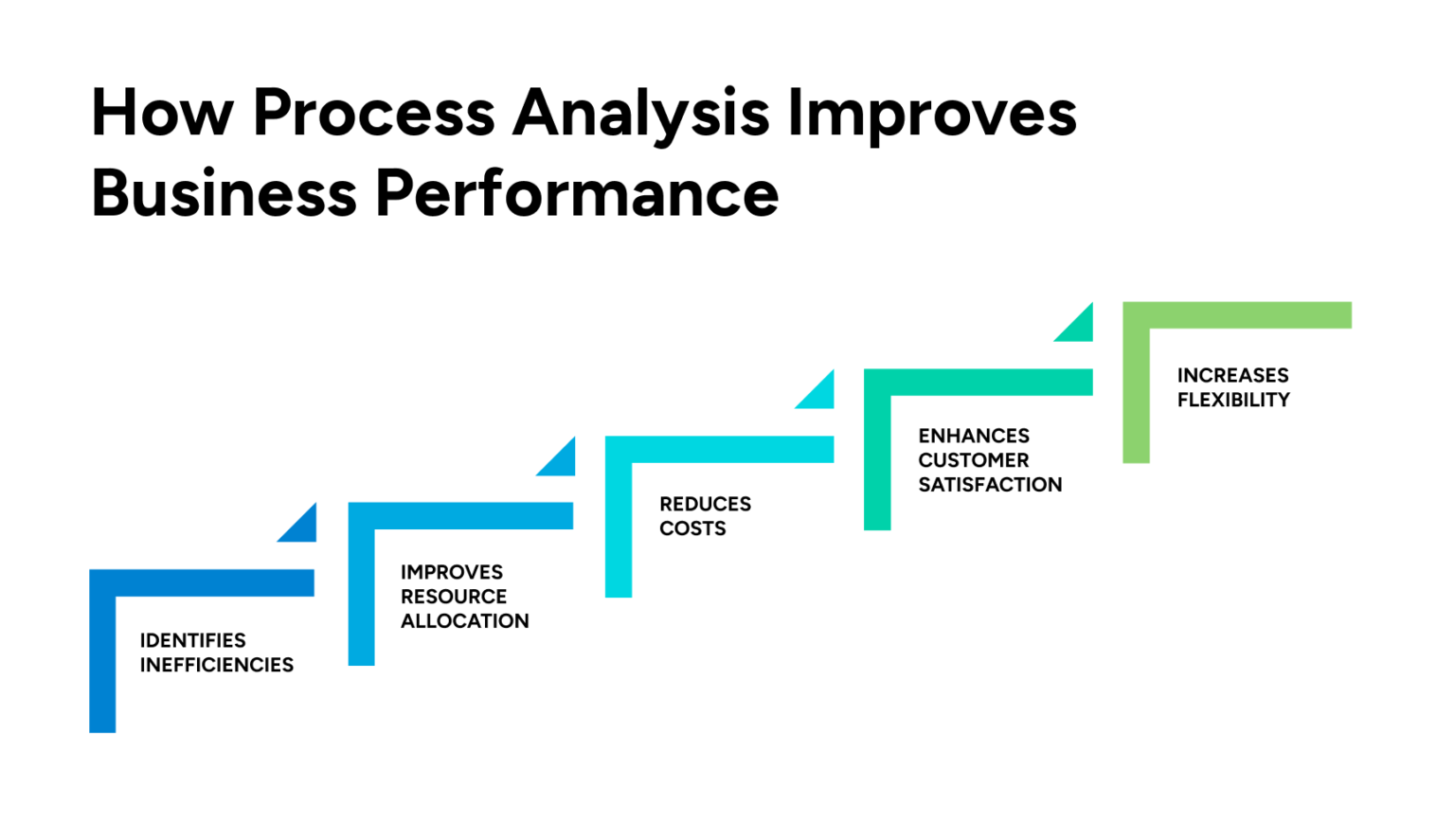

How Process Analysis Improves Business Performance

Conducting regular Process Analysis is essential for maintaining operational efficiency and competitiveness. Here’s how it benefits businesses:

- Identifies Inefficiencies: Process Analysis pinpoints areas where time, money, and resources are being wasted, allowing businesses to implement corrective actions.

- Improves Resource Allocation: By identifying bottlenecks and inefficiencies, companies can reallocate resources where they are needed most, ensuring that workflows run smoothly.

- Reduces Costs: Process optimization can lead to reduced operational costs, especially when inefficiencies are eliminated, or resources are better managed.

- Enhances Customer Satisfaction: Faster, more efficient processes often lead to improved customer experiences, as products and services are delivered more quickly and reliably.

- Increases Flexibility: With continuous Process Analysis, businesses can quickly adapt to changes in demand or market conditions, ensuring they remain agile and competitive.

Why Process Analysis is Key for Continuous Improvement

Continuous improvement is a fundamental principle in modern business management, and Process Analysis is at the heart of it. By regularly reviewing and optimizing processes, businesses can avoid stagnation and maintain a cycle of constant growth and innovation.

Whether your organization is large or small, Process Analysis can help you stay competitive by ensuring that your processes are as efficient and effective as possible.

Optimize Your Business with Process Analysis

In today’s competitive market, businesses must operate efficiently to thrive. By conducting thorough Process Analysis, identifying bottlenecks, using root cause analysis tools like the Fishbone Diagram and 5 Whys, and monitoring performance metrics and KPIs, you can drive significant improvements in operational efficiency.

For companies looking to optimize their processes and maximize productivity, investing in regular Process Analysis is the first step toward achieving long-term success. By leveraging this critical aspect of Business Process Management (BPM), your organization can stay ahead of the curve, reduce inefficiencies, and deliver better value to customers.